Polysulphide Impression Material, a type of non-aqueous elastomeric impression material, was developed to overcome the limitations of hydrocolloids, offering both dimensional stability and elasticity.

Polysulphide Impression Material, a type of non-aqueous elastomeric impression material, was developed to overcome the limitations of hydrocolloids, offering both dimensional stability and elasticity.

Definition of Polysulphide: Polysulphide is an elastic impression material characterized by an SH group-terminated polymer. The material undergoes catalysis by Lead Dioxide to facilitate its setting reaction.

Manipulation Technique:

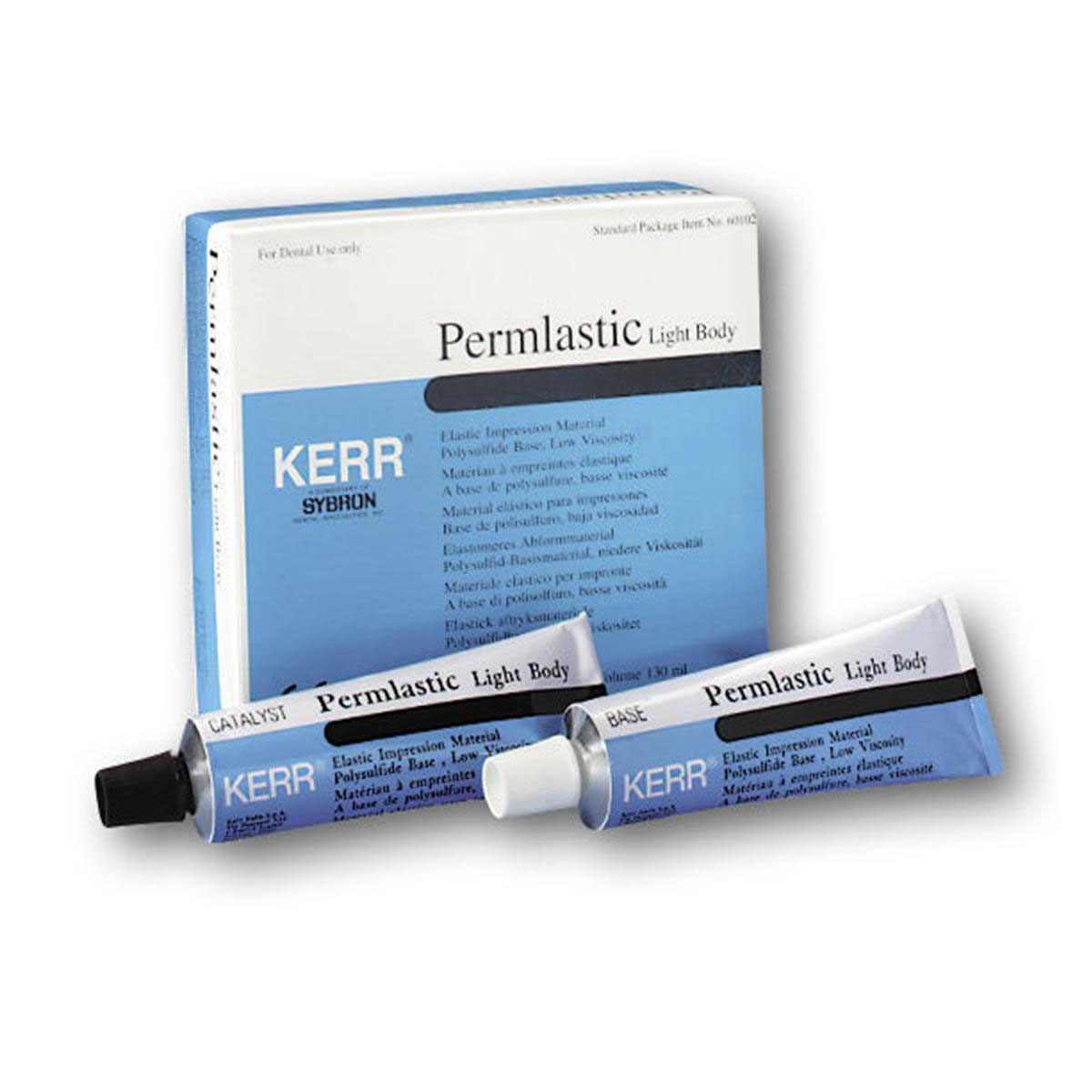

- Consistency Variations: Polysulphide Impression Material is available in three consistencies: light, medium, and heavy-bodied. These variations cater to different clinical requirements and preferences.

- Mixing Process: Equal portions of the base and catalyst pastes are dispensed and mixed on an oil-impervious paper pad. The goal is to achieve a uniform, homogeneous color without any streaks of base or catalyst paste. Proper mixing is crucial to ensure the material’s effectiveness and consistency.

- Loading and Insertion: Once mixed, the impression material is loaded onto a special tray and inserted into the patient’s mouth. Careful positioning and handling are necessary to ensure accurate impression-taking.

- Setting Time: Polysulphide impression material sets over a specific period after insertion into the mouth. The setting time varies depending on factors such as temperature and the specific formulation of the material.

- Odor Concerns: It’s important to note that polysulphides often have an unpleasant odor due to the presence of mercaptan groups. Dental professionals and patients should be aware of this characteristic during the impression-taking process.

Presentation

Polysulphide impression material is available in three main consistencies: light-bodied, medium-bodied, and heavy-bodied. Each consistency serves specific purposes in dental impressions:

- Light-Bodied Polysulphide:

- Light-bodied polysulphide has a thinner consistency, similar to a fluid or gel.

- It is commonly used for capturing fine details and intricate areas of the oral cavity, such as around narrow margins and deep undercuts.

- This consistency flows more easily into the desired areas and ensures accurate reproduction of surface details.

- Medium-Bodied Polysulphide:

- Medium-bodied polysulphide has a slightly thicker consistency compared to the light-bodied version.

- It strikes a balance between flowability and stability, making it suitable for general impression-taking procedures.

- Dentists often use medium-bodied polysulphide for making preliminary impressions of both dentate and edentulous arches.

- Heavy-Bodied Polysulphide:

- Heavy-bodied polysulphide is the thickest consistency among the three.

- It has a dense, putty-like texture that provides excellent support and stability.

- This consistency is ideal for making custom trays or impression trays with deeper impressions, where additional material stability is required.

- Heavy-bodied polysulphide ensures optimal adaptation to the tray and the oral tissues, facilitating accurate and reliable impressions.

Manipulation of each consistency of polysulphide impression

The manipulation of each consistency of polysulphide impression material involves specific techniques tailored to their unique properties and intended applications:

- Light-Bodied Polysulphide:

- Dispensing: Light-bodied polysulphide is dispensed using a syringe or a small dispensing gun equipped with a fine-tip nozzle.

- Loading: Carefully load the material into the desired areas of the prepared tray or directly into the oral cavity.

- Injection: Use gentle pressure to inject the light-bodied polysulphide around fine margins and intricate details of the teeth or soft tissues.

- Technique: Employ a slow and controlled injection technique to ensure precise placement and adequate coverage of the critical areas.

- Removal: Once set, remove the impression gently to avoid distortion, ensuring accurate reproduction of delicate structures.

- Medium-Bodied Polysulphide:

- Mixing: Dispense equal amounts of the base and catalyst pastes onto a mixing pad.

- Homogenization: Use a spatula to blend the pastes thoroughly until a uniform color and consistency are achieved.

- Loading: Transfer the mixed medium-bodied polysulphide onto the prepared tray using a spatula or impression gun.

- Tray Placement: Seat the loaded tray in the patient’s mouth, ensuring even pressure for uniform adaptation to the oral tissues.

- Set Time: Allow sufficient time for the material to set according to the manufacturer’s recommendations before removal.

- Heavy-Bodied Polysulphide:

- Mixing: Mix the base and catalyst pastes together thoroughly until a consistent color and texture are obtained.

- Loading: Place the mixed heavy-bodied polysulphide into the tray, ensuring complete coverage of the impression surface.

- Tray Insertion: Seat the tray firmly in the patient’s mouth, applying gentle pressure to ensure adequate adaptation to the oral tissues.

- Set Time: Allow adequate time for the material to set completely before removing the impression from the mouth.

- Removal: Carefully remove the set impression from the mouth, ensuring minimal distortion or displacement of the material.

Characteristics of Polysulphide

Composition:

Base Paste:

- Polysulphide Prepolymer: Comprising 80-85% of the base paste, this component contains terminal and pendant thiol (-SH) groups. During polymerization, these groups cross-link to form a rubber-like material, contributing to the elasticity of the final impression.

- Plasticiser: Typically di-n-butylphthalate, this additive serves to control the viscosity of the base paste, ensuring proper flow and workability.

- Inert Filler: Constituting 16-18% of the base paste, inert fillers such as chalk or titanium dioxide are incorporated to provide body to the material, regulate viscosity, and modify its physical properties.

Catalyst Paste:

- Lead Dioxide (PbO2): The primary oxidizing agent, comprising 60-68% of the catalyst paste. Lead dioxide reacts with thiol groups present in the base paste, initiating the setting reaction.

- Sulphur: Constituting 3% of the catalyst paste, sulphur plays a crucial role in the setting reaction, facilitating the cross-linking of polysulphide chains to form a stable impression.

- Inert Oil: Typically paraffinic or di-n-butylphthalate, this component constitutes 30-35% of the catalyst paste. It acts as a vehicle for PbO2 and sulphur, forming a paste that enables uniform mixing and reaction.

Setting Reaction of Polysulphide

Upon mixing the base and catalyst pastes of polysulphide impression material, a chemical reaction is initiated. This reaction involves the oxidation of thiol (-SH) groups present in the polysulphide prepolymer by the catalyst lead dioxide (PbO2).

During this oxidation reaction, a cross-linking process occurs. This cross-linking reaction is partially of the condensation polymerization type, leading to the formation of chemical bonds between adjacent polysulphide chains. As a result of these cross-links, one molecule of water is produced as a by-product of certain reaction stages.

Effect of By-Product on Impression Material

The production of water as a by-product during the setting reaction can have implications for the accuracy of the impression material. Excessive moisture can affect the dimensional stability of the material, potentially leading to distortion or inaccuracies in the final impression.

Therefore, it is essential to control the moisture content during manipulation and setting to ensure optimal performance and accuracy of the polysulphide impression. Additionally, proper handling techniques and timely removal of the impression from the mouth can help minimize the impact of moisture on the final result.

Modification of Polysulphides

In response to concerns about the toxicity of lead compounds and to improve handling characteristics, modifications have been made to polysulphide impression materials. Here are the key modifications:

- Substitution of Lead Dioxide: Hydrated copper oxide (Cu(OH)2) has been introduced as a substitute for lead dioxide (PbO2) in polysulphide formulations. This substitution results in a green-colored mix, providing an alternative catalyst for the setting reaction. The use of copper oxide eliminates the potential toxic effects associated with lead compounds, addressing safety concerns for both patients and dental professionals.

- Alternative Accelerator Systems: Zinc carbonate, sometimes combined with organic accelerators, has been employed as an alternative to lead dioxide in polysulphide impression materials. This replacement aims to enhance the handling properties of the material while maintaining its setting characteristics. The use of zinc carbonate offers a cleaner and safer option for dental practitioners, reducing potential health risks associated with lead-based formulations.